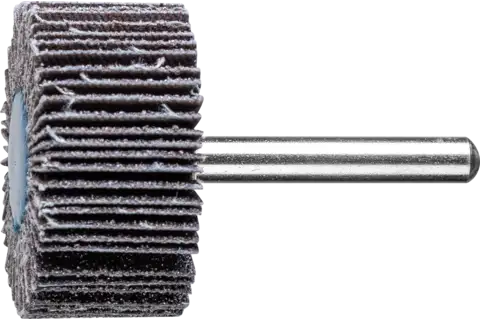

Mounted flap wheels

SIC mounted flap wheel F dia. 40x20 mm shank dia. 6 mm SIC60 for hard non-ferrous metals

Technical information

SIC mounted flap wheel F dia. 40x20 mm shank dia. 6 mm SIC60 for hard non-ferrous metals

- Abrasive

- Silicon carbide SiC/C

- Dia. external

- 40 mm

- Dia. shank

- 6 mm

- Grit size

- 60

- Length, shank

- 40

- Max. RPM

- 19100 RPM

- RPM, optimum

- 9600 RPM

- Width

- 20 mm

- Packaging unit

- 10 pieces

Description

Advantages

Recommendations for use

Safety notes

- Materials that can be worked

- Applications

- Drive types

PFERDVALUE

PFERDERGONOMICS

recommends mounted flap wheels to sustainably reduce the vibration and noise produced during use and to improve comfort when working.