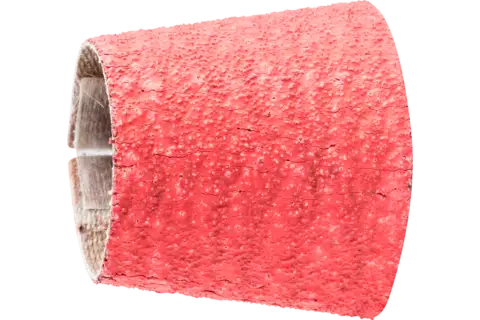

Abrasive spiral bands, conical

ceramic oxide grain abrasive spiral band GSB conical dia. 22-29x30mm CO-COOL80 for maximum stock removal on stainless steel

Technical information

ceramic oxide grain abrasive spiral band GSB conical dia. 22-29x30mm CO-COOL80 for maximum stock removal on stainless steel

- Abrasive

- CO-COOL

- Dia internal

- 29 mm

- Dia internal, small

- 22 mm

- Dia. external

- 28 mm

- Grit size

- 80

- Height

- 30 mm

- RPM, optimum, from

- 13000 RPM

- RPM, optimum, to

- 19100 RPM

- Packaging unit

- 100 pieces

Description

Advantages

Recommendations for use

Ordering notes

Safety notes

- Materials that can be worked

- Applications

- Drive types