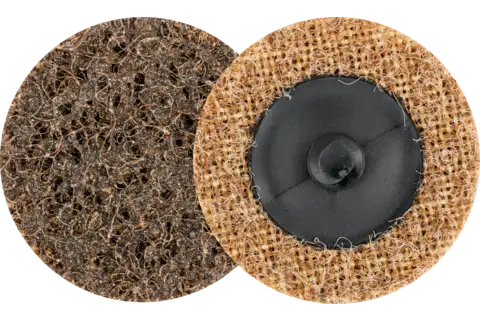

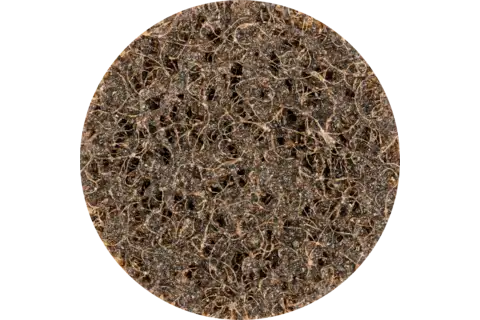

COMBIDISC non-woven discs VRH CD/CDR

COMBIDISC hard non-woven disc CDR dia. 50 mm A100G for fine grinding and finishing

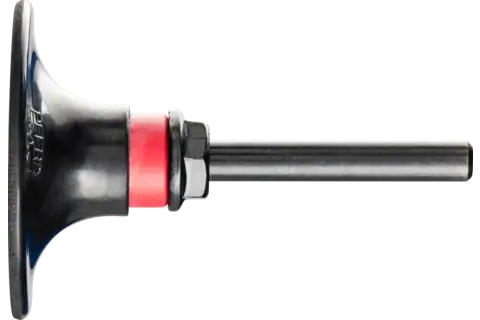

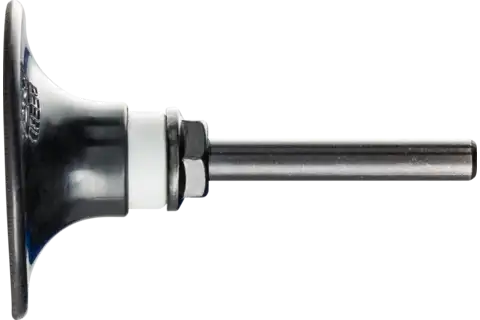

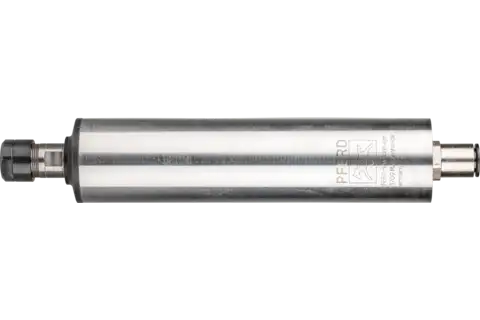

Matching accessories & spare parts

Technical information

COMBIDISC hard non-woven disc CDR dia. 50 mm A100G for fine grinding and finishing

- Abrasive

- Aluminium oxide A

- Clamping system

- CDR system

- Dia. external

- 50 mm

- Grit size

- 100 G

- RPM, optimum, from

- 5500 RPM

- RPM, optimum, to

- 7500 RPM

- Version

- coarse, yellow-brown

- Packaging unit

- 50 pieces

Description

Advantages

Recommendations for use

Ordering notes

Safety notes

- Materials that can be worked

- Applications

- Drive types

PFERDVALUE

PFERDEFFICIENCY

recommends COMBIDISC tools to reduce tool changing and setting-up time.

PFERDERGONOMICS

recommends COMBIDISC as an innovative tool solution to sustainably reduce the vibration, noise and dust produced during use and to improve comfort when working.