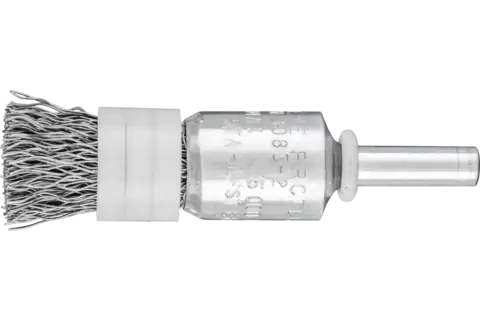

End brushes crimped with bridle, shank-mounted

End brush with bridle crimped PBUR dia. 13 mm shank dia. 6 mm steel wire dia. 0.35

Technical information

End brush with bridle crimped PBUR dia. 13 mm shank dia. 6 mm steel wire dia. 0.35

- Dia. cup

- 16 mm

- Dia. external

- 13 mm

- Dia. filament material

- 0.35 mm

- Dia. shank

- 6 mm

- Filament material

- Steel wire (ST)

- Grit size

- No information

- Length, filament

- 25 mm

- Length, filament to ring

- 13 mm

- Length, total

- 2 3/4

- Length, total

- 70 mm

- Max. RPM

- 15000 RPM

- Mounting system

- Shank

- RPM, optimum, from

- 7500 RPM

- RPM, optimum, to

- 11300 RPM

- Packaging unit

- 10 pieces

Description

Advantages

Recommendations for use

Safety notes

- Materials that can be worked

- Applications

- Drive types