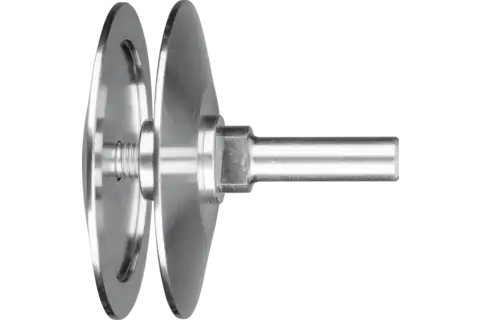

Wheel brushes crimped Composite, with hole

COMPOSITE wheel brush RBUP dia. 150x13x50.8 mm hole ceramic filament dia. 1.10 mm grit 120 stationary

RBUP 15013/50,8 CO 120 1,10

Matching accessories & spare parts

Technical information

COMPOSITE wheel brush RBUP dia. 150x13x50.8 mm hole ceramic filament dia. 1.10 mm grit 120 stationary

- Dia. external

- 150 mm

- Dia. filament material

- 1.1 mm

- Dia. hole

- 50.8 mm

- Filament material

- Ceramic oxide grain (CO)

- Grit size

- 120

- Length, filament

- 32 mm

- Max. RPM

- 3600 RPM

- Mounting system

- Centre hole

- RPM, optimum

- 900 - 1.500 RPM

- Width

- 13 mm

- Packaging unit

- 1 piece

Description

Advantages

Recommendations for use

- Materials that can be worked

- Applications

- Drive types

PFERD TOOLS VALUE

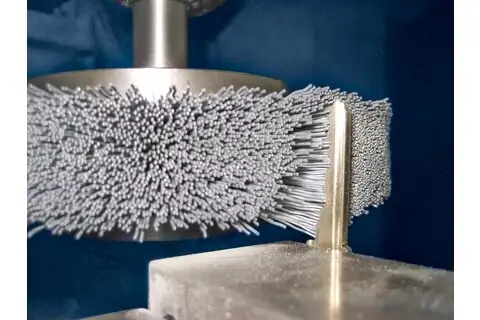

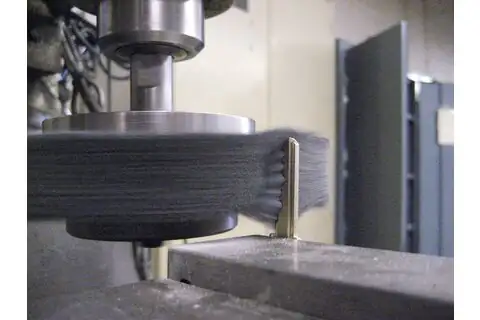

PFERD TOOLS EFFICIENCY

recommends composite brushes to achieve maximum stock removal as quickly as possible.

PFERD TOOLS ERGONOMICS

recommends composite brushes to sustainably reduce the vibrations produced during use.